Brand new cars from MIL, Sorel, QC., being moved for delivery to the Prairies by CNR. Walkley yard, by pass track Ottawa

Government of Canada Hopper Cars being scrapped at Welland, Ont., 2021 Joseph Bishop photo

The Beginning by Colin J. Churcher

I

was responsible for "buying" a large proportion of the government grain

hopper fleet while working in grain transportation for Transport Canada

(1975-1986).

The bulk of the brown and yellow fleet as well as all the red and black cars were purchased by the federal government (13,500 cars).

The Canadian Wheat Board acquired 4,000 brown and yellow cars. The

provinces of Saskatchewan and Alberta each bought 1,000 cars. The brown

and yellow scheme was chosen by Otto Lang, then Minister Responsible

for the Canadian Wheat Board, as being non-partisan. The red and black

scheme was chosen by Senator Argue, a later Minister Responsible for

the Canadian Wheat Board.

Original Government of Canada scheme

Photo thanks to Eric Gagnon |

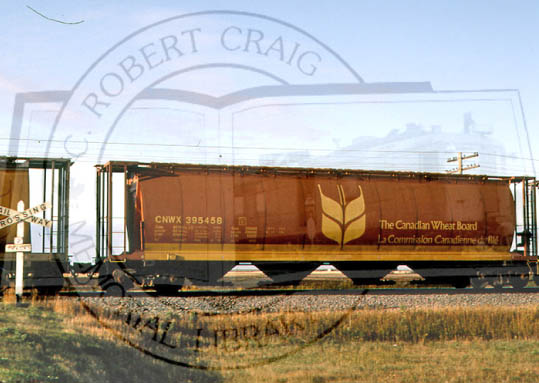

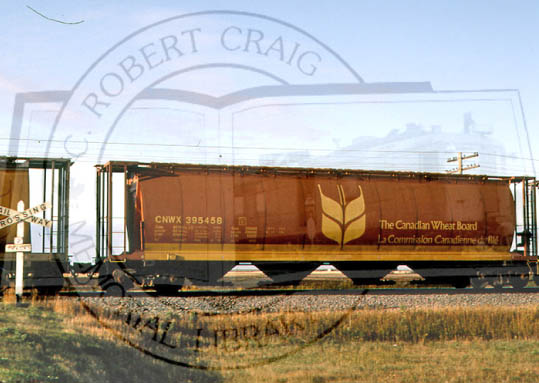

Canadian Wheat Board scheme.

Ken Healy photo.C. Robert Craig Memorial Library 38010

|

Original livery Saskatchewan car at Smiths Falls

Bruce Chapman collection C. Robert Craig Memorial Library No. 62379 |

Second livery Saskatchewan car at beechy, SK. on 25 August 2018

Raymond Farand photo

|

Alberta. Photo thanks to Eric Gagnon |

The steel hoppers were put into

service very quickly and were praised at the time for their greater

capacity and lower center of gravity with their four unloading hoppers.

Initial problems were experienced both on the prairies and at the

ports.

On the prairies the country elevators had to be

modified with higher loading spouts. A number of elevator

managers fell into the hoppers through the top hatches and could not

get out on their own. We solved this by putting a grating over the

opening.

Another problem experienced by the prairie elevator

managers was that the hopper cars with roller bearings ran much more

easily than the journal bearing boxcars they replaced. The elevator

operators asked that the cars be modified to have a hand brake

operating wheel on both ends of the car. This was rejected by the

railways as causing potential operating problems

At the ports

some difficulty was experienced in opening the discharge gates.

Some gates even became so stiff that they had to be cut off to allow

unloading. Eventually the gates were modified to a more satisfactory

system which could be operated with mechanical assistance.

One

of the problems experienced with the steel hoppers was harmonic motion.

The distance between the leading wheel of the front truck and the

leading wheel of the rear truck was forty feet. This was the same as

the rail lengths before extensive use of continuous welded rail.

With rail staggered joints a dangerous harmonic motion could develop.

For this reason trains which had these cars in the consist could not be

operated between 18 mph and 22 mph (I believe this was the range).

Engineers were only allowed to accelerate or decelerate their trains

through this speed range. There was another danger range around 60-70

mph I believe.

Jerry Pinkepank writes: The rock and roll issue was dealt with by constant contact side bearings https://www.youtube.com/watch?v=IeMEKu8HLFQ

which were available in the early 80’s and I suspect they were

retrofitted on these cars. The 60-70mph problem would have been truck

hunting and the constant contact side bearings also deal with

that. I suspect the elimination of these cars from the fleet is

due to the move to 286,00 lb. and 316,000 lb. gross rail load cars in

place of the 263,000lb car prevailing in the early 80’s. This has

also culled 263,000lb cars out of the coal fleets.--Jerry

Some

time after I was called to testify before the Anti-Dumping Tribunal. It

turned out that we were buying some parts (wheels, I believe) from

Brazil that were cheaper, including transportation to Nova Scotia, than

they could be manufactured in the Trenton plant. I heard nothing

further.

The CNR line to Churchill

For

similar reasons CNR would not allow these hoppers to be used on the

line to Churchill, which was always difficult because much of it was

laid on permafrost. This was why the federal government agreed to

renovate a number of 40 foot boxcars for use on the line to Churchill.

It should be noted that when the Churchill line was privatized hopper

cars did make it to Churchill.

Transport Canada also funded the

construction of an articulated car which might have performed well on

the line to Churchill. However development did not go any further

than the prototype.

The Aluminum Cars

William A. Crago photo.

Ordering the Cars

The

government cars were built in several orders. We obtained prices

and delivery from the three suppliers, National Steel Car, Hamilton,

Ont., MIL, Sorel, Que., and Hawker-Siddeley, Trenton, NS. In each case

the cabinet decided to spread the order rather than choosing the lowest

cost from one manufacturer.

Northern Alberta Railway

In

the mid-1970s the Northern Alberta Railway (NAR) was an independent

line wholly owned by CNR and CPR. Initially neither CNR nor CPR would

allocate hopper cars to the NAR and I began negotiations for the NAR to

have its own separate allocation. There was talk in Edmonton of a

separate NAR livery. However, in the end I was able to persuade CNR

and CPR to allocate hopper cars to the NAR from within their own

allocation.

My

discussions with Jim Pitts, the NAR General Manager covered a wide

range of subjects as well as hopper cars. One of the outcomes was

to name the NAR locomotives in a manner similar to locomotives in the

UK.

Using the Cars

The

rationale for buying hopper cars was that the railways were losing

money moving grain under the statutory Crow’s Nest Pass rates.

Hopper cars were seem as short term assistance until the rate problem

could be resolved. Because if this the government cars could only be

used by the railways to move grain moving at the Crow Rate. This

restricted their use to wheat, oats, barley, rye, rape (canola) and

flax moving from the prairies to Thunder Bay, (Churchill) and the west

coast ports for export. This did apply to grain moving to the Victoria

elevator until it closed but not to domestic points on Vancouver Island.

The

railways were charged whenever a car was used in domestic service. For

many winters there was a heavy movement of grain in solid trains of

hopper cars east of Thunder Bay to Montreal and Halifax (and possibly

Saint John, NB.). These were made under an agreed payment with the

government for their use. This was lucrative traffic for CNR and CPR.

The two railways originally agreed to split the traffic by number of

trains. CPR stole a march on CNR by running 99 car trains whereas

CNR was only able to run trains of 98 cars. Over the winter this

resulted in a significant financial advantage to CPR.

The hopper

cars were occasionally used for non-grain movements with payment to the

government. For example they were used by CPR to move drilling mud to

Alberta.

One of the pleasures of my job at that time was

to attend the sample car inspections. At the commencement of each

order the manufacturer would complete one car and the railway

mechanical people would go over that car in fine detail to ensure that

it conformed to the plans. The car was then kept at the plant so that

if there were any problems later on in the production process these

could be verified by reference to the approved model. Here are

two pictures I took at Hamilton in August 1982.

Sample car ar National Steel Car, Hamilton, August 1982.

Sample Car at National Steel Car, Hamiltom. August 1982

From left to right John Nelham, NSC; Paul Churcher; Colin Churcher

The Demise of the Government Cars

The decomissioning of the cars was not straight forward as Bernie Geiger remembers (June 2021)

The

disposal of the cars was not straight forward as the government laws

and policy requirements have complex approval and reporting

requirements to write-off and / or transfer to other operators.

There was some Central Agency discussion as to whether the actions

could be reported as groups of cars in the Public Accounts or

individual numbers needed to be given for each individual car.

I remember it was often difficult to "donate"

federal government items to museums because you had to adhere to

various disposal requirements and there is really no easy way to "gift"

something like a (railway) artifact, image, souvenir, etc to a museum

or library.

Perhaps it was easiest to throw it in the

"garbage" and tell someone to pick it out of the garbage before it was

hauled away.