Blocking Trains

I recently earned a few brownie points on the St. Francis Valley

Railway because, being operator at Sorel, I blocked train 394 back to front.

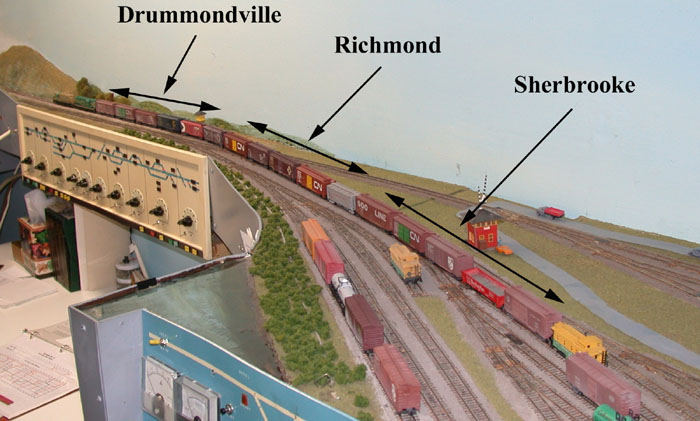

394 is a through freight running on the SFV between Sorel and Sherbrooke.

It is a hot train which must run to time and so it is blocked so that intermediate

work can be carried out quickly. Cars for this train are sorted into

blocks by destination and it should leave Sorel with the Drummondville block

on the front, the Richmond block in the middle and the Sherbrooke cars on

the rear.

At Drummondville the yard switcher puts a block of cars for Sherbrooke inside

the caboose while the train engine sets out the Drummondville cars (cars

from Drummondville for Richmond are sent on the way freight). Arriving

at Richmond, it is a quick move using the train locomotive to set out the

Richmond block and pick up the Sherbrooke block. The train now runs

to Sherbrooke as a solid block. (See illustrations at the end of this article)

This is a method of operation which is used by many railways. We used

it on British Railways but there were complicating factors:

Whether the cars were fitted with vacuum or air brakes or no

continuous brakes at all.

Whether the cars were fitted with vacuum or air brakes or no

continuous brakes at all.

Was the train locomotive equipped with vacuum or air brakes,

or both.

Was the train locomotive equipped with vacuum or air brakes,

or both.

In the 1960’s we were running a lot of freight trains with freight cars

with no brakes. In order to run trains a little faster we would put

the braked cars on the front where they could be hooked up to the engine

(known as a fitted head) and leave the unbraked portion on the rear.

Close co-ordination was required between the engineer and the conductor to

ensure that the conductor used the hand brake in the caboose to provide extra

braking effort when it was required.

Using 394 as an example, we would have made it up with twice the number

of blocks leaving Sorel:

Drummondville - continuous braked

Richmond – continuous braked

Sherbrooke – continuous braked

Sherbrooke – non-braked

Richmond – non-braked

Drummondville – non-braked

This was complicated even further by the fact that many non-braked cars

had a through vacuum pipe but no continuous brakes. This was helpful

in that it eased the switching problems but would easily lead to confusion

as we shall soon see. Through pipes were painted white at the end while

the pipes of fully braked cars were painted red.

If this wasn’t bad enough, at that time British Railways was changing over

from vacuum brakes to air brakes and new cars were coming out of the shops

with air brakes. Now the problem was not only to provide a fitted head

but to provide a locomotive with the correct braking system.

At one time, I was Area Manager, Haverfordwest, in west Wales. I came

into work one morning and found a group of about ten large tank cars, all

brand new with a coat of gleaming fresh paint. It turned out that this

train had originated in Fishguard the previous night. The yardmen had

connected up the white vacuum painted brake pipes to a Hymek diesel which

was equipped with the vacuum brake. There was a quick brake test and

the brakes applied on the caboose. Having assembled the train in the

dark, aided only by a couple of oil hand lamps, they didn’t realise that the

entire train was only piped. They started up the steep grade from Fishguard

in fine style and crested the grade when the train began to gather speed.

A quick application of the vacuum brake produced no noticeable effect.

The engineer looked across to the second man and gave it a hard application

and it became apparent that they had a runaway on their hands. However,

the section was a long one and they managed to get the train under control

by the time they had reached Clarbeston Road. The crew, thoroughly

scared, dumped the train in my yard and went home to Llanelli, leaving me

with the problem.

A call to Control provided a solution – sort of. They would give me

an air braked locomotive but I had to get the train ready. This was

the first time any of us at Haverfordwest had seen an air brake pipe.

The ends had been given a thick coat of paint and, to make it worse, this

was a two pipe system and we weren’t sure which pipes had to be connected

to which. The paint was so thick and the ends so stiff that we spent

the entire morning and managed to connect up just four cars. I decided

that we had enough of an air braked fitted head to get rid of this train which

was filling the yard and everyone was glad to see the back of it.

About the only benefit from this episode was that I was able to learn a

number of Welsh swear words. The air turned blue as we struggled to

couple up those pipes.

Train blocking is a good method of operating any railway although

it does cause a little more work in the originating yards. So if you

are having trouble getting a train properly blocked and out on time just remember

that it could be a whole lot worse if you had to worry about things such

as the colour of the brake pipes and the type of locomotive to be supplied.

Train 394 is leaving Sorel on June 11, 1965 correctly

blocked. At Drummondville the front block will be set out by the train

locomotive while the yard switcher will add Sherbrooke cars inside the caboose.

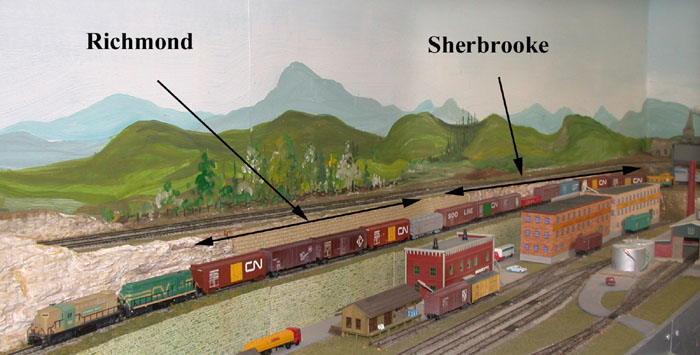

Having completed its work at Drumondville, train

394 is leaving for Richmond blocked in two sections.

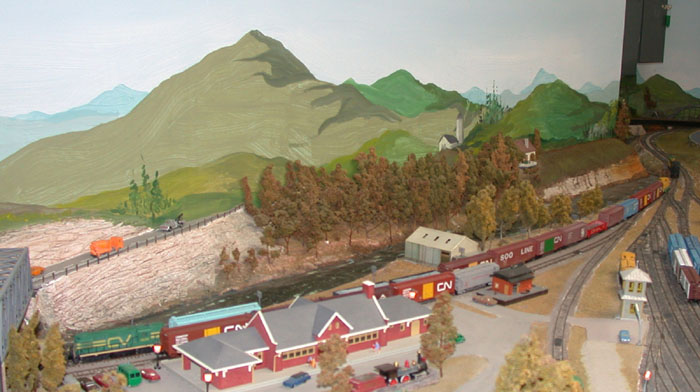

Train 394 has completed its work at Richmond and

is about to leave for Sherbrooke. The train locomotives have set out

the Richmond block, standing on the platform track by the station, and picked

up cars for Sherbrooke. 394 is now a solid train of cars for Sherbrooke.

Ottawa Valley Associated Railroaders

- OVAR, The Interchange, June 2005.

Whether the cars were fitted with vacuum or air brakes or no continuous brakes at all.

Was the train locomotive equipped with vacuum or air brakes, or both.