Brick manufacturing started in the Russell area in 1864 and by 1895 there were three separate brick factories operating in the township. On 23 January 1907 the brick making operation of John A. and Horatio Loucks was sold to the Russell Brick and Tile Company. The clay was found to be too soft for the manufacture of bricks but good, workable shale was found about two and a half miles north and an open pit operation was commenced.Narrow gauge 0-4-0 saddle tank locomotive used to move shale from the pit alongside the road to the brick plant at Russell. Colin J Churcher collection, Russell Historical Society, Russell Museum 989.80.1.

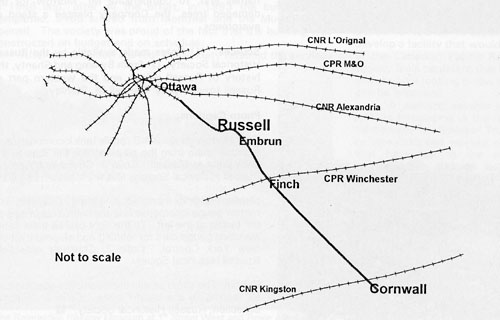

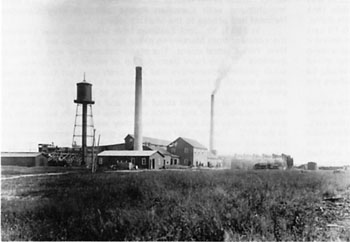

A new company was organized as Russell Shale Bricks which purchased the holdings of the Russell Brick and Tile Company in late 1911. The new company built a new factory which was completed late in 1912. This was located to the east of Russell on the road to Embrun close to the New York Central railway line. Three sidings were built into the plant for the loading and unloading of railway cars. The new plant was one of the most modern in the country and Russell bricks were shipped to Ottawa, Montreal and as far afield as New York City. In 1913, a right of way, one rod (a rod is 5 ½ yards) wide, was obtained from the various farmers along the west side of the concession road (between concessions 3 and 4). Some reluctantly sold the land required while others gave the necessary land. A three-foot gauge railway was built along this right of way from the brickyard to the shale pit. A small 0-4-0 saddle tank locomotive was brought in to work the railway. Small, side dump, four wheel cars were loaded with shale at the pit and 16-18 cars would be hauled down the road to the brick factory. On arrival it would pull into a siding and push 2 or 3 cars at a time up a ramp and into the crushers. The shale was crushed and then mixed with clay. When all the cars had been unloaded they would be assembled into a train of empties and return to the pit where the cycle would recommence. The shale was loosened with dynamite. The narrow gauge tracks would be placed as close to the pit face as possible so that the explosion would drop as much shale as possible into the cars. The rest had to be loaded by hand. A steam shovel, which also used three foot gauge tracks, was brought in to assist in the loading operation. It arrived at Russell on a NYC flatcar and had to be moved along the middle of the road to the pit. Men had to lay 60 feet of track ahead of the shovel which was pulled ahead by a team of horses. The track was then picked up from behind the machine and laid ahead and the operation was repeated. It took two days to move it to the shale pit. Tom Kinchen and his father stayed with the shovel all night to guard it against vandals. The 1914-18 war brought a slump in the demand for bricks. The main market for Russell bricks was Montreal with the cars being interchanged to the Canadian Pacific at Finch. Russell bricks were in competition with the Laprairie Brick Company which purchased the Russell Company in 1923 and closed the plant later the same year. The entire operation was sold to Zagerman Brothers of Ottawa on 30 October 1929 on condition that all the buildings be demolished. On 24 November 1929 Zagermans resold it, including the shale pit and the roadside tramway, to Duncan Merkley who owned a brickyard at Billings Bridge in Ottawa which was served by the Canadian National (formerly Canadian Northern Ontario) Railways. Construction of the Merkley siding at mile 3.1 of the Beachburg subdivision was authorized by order 32155 of 25 Feb 1922 and an extension was authorized by order 37985 of 15 Aug 1926. Shale was loaded at the NYC into freight cars and moved to the NYC Mann Avenue yards where it was interchanged for movement to the Merkley siding. Notes in the Russell Museum suggest that the cars were interchanged with Canadian Pacific although only Canadian National had access to the Merkley siding. In 1931, Mr. Jack Eastman from Marvelville was awarded the contract from Merkley to move the shale from the pit to the NYC depot. The steam locomotive was no longer available – it may have been cut up or resold by Zagerman. A small gasoline locomotive had also been tried but this was not strong enough to haul the loaded cars out of the pit. Mr. Eastman used two grey horses, Jack and Prince, to move the shale cars. Each car weighed about a ton and would carry about 3 ½ tons of shale. Jack and Prince could haul two cars out of the pit and when they had six assembled they would move these down to the NYC. The first half mile was up grade and sometimes their stomachs would be about 6 inches above the rails. At the high point, the teamster would pull the pin on the whiffletrees and the horses would step aside and walk beside the cars to allow the train to coast down grade for about a mile. When the cars had come almost to a stand the team would be waiting for the teamster to drop the pin in the whiffletree for the rest of the run. The team was so well trained the teamster did not need to use lines to guide them. At the NYC, the horses would be unhitched and a one horse power gasoline engine was used to work a winch which pulled the cars up a ramp to be unloaded into open freight cars. The team would return the empty cars to the pit and, if not needed for another trip, the horses would be unhitched and put into a building out of the sun where they would be watered and given oats and hay. This was a seasonal operation and the pit had to be pumped out every spring before work could commence. Due to poor maintenance of the standard gauge sidings, the NYC refused to take a locomotive into the loading yard. The horses were then used to draw out the cars onto the main track where the locomotive could get hold of them. The horse drawn operation lasted for seven years. It then became too expensive to transfer the cars from the NYC to the Merkley siding in Ottawa. In 1938 Mr. Eastman purchased a 1937 Maple Leaf truck and trucked the shale directly to the Merkley plant. In the late 1940’s or early 1950’s Jack Eastman gave up his contract. In March 1950 Merkley sold the Billings Bridge plant which allowed construction of the easterly part of the shopping centre up to the current Loblaws store. The brick plant was to the south-west and continued. In 1959, as Merkley was planning an expansion of the business, the government expropriated the property and demolished the plant. The Russell shale pit was sold to the Ottawa Brick and Terra Cotta Company which sold it to Domtar on 25 January 1960. Shale is still being trucked out of the pit to the Domtar brick plant at Leitrim. Five cars were dragged out of the shale pit in 1992 and are now stored in the Manotick area. They had been partly covered by overburden. These have a steel frame and a steel, side tipping, body. A photograph taken in the pit, which shows the steam locomotive and steam shovel, shows a number of wooden bodied cars so the surviving cars do not appear to be original. The wheel gauge has been verified as three feet. Four of the cars have no brakes while one was fitted with a hand operated brake with the shoes working on all four wheels. They are all fitted with a link and pin coupler and draft gear at one end only. A few photographs exist of the narrow gauge railway including a good side view of the locomotive which cannot be identified as to maker. No photographs of the gasoline locomotive, or the two horse power locomotive Jack – Prince, have yet come to light. There is little to be seen today of this interesting

roadside tramway. At one point along the road can be seen

a stand of evergreen trees which is a reminder of the railway.

One day the engineer decided to stop and empty the ashpan of the locomotive.

He continued on to the brickyard with his load and on the return trip

he found the brush on fire. The men were able to put out the

flames and, to compensate Mr. Morrow for the damaged trees, the Company

planted a stand of evergreens.

Bytown Railway Society, Branchline, June 2001. |

||||||||